UNIQE 3D PRINTING CAPABILITIES

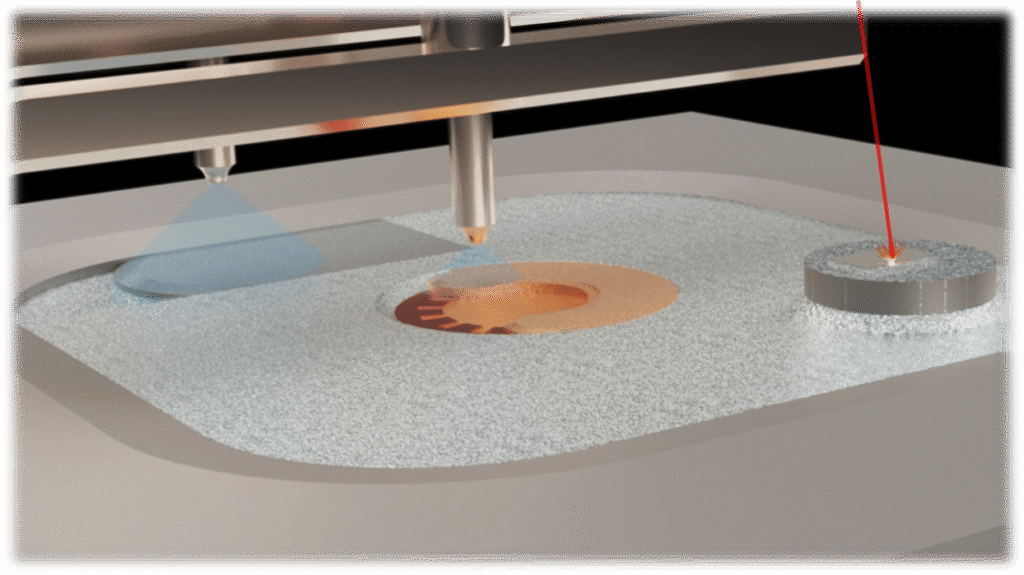

Originally developed for in-space additive manufacturing (ISAM) and the constraints of microgravity, Spaceform’s suspension-based process is engineered to unlock capabilities far beyond what is achievable with today’s powder-bed systems. By combining controllable suspension deposition with precise laser consolidation, the technology is designed to support complex geometries, smooth multimaterial transitions, and inherently stable, supportless printing across metals, ceramics, and polymers. This approach will dramatically reduce reliance on costly spherical powders and enable the use of alternative, more sustainable feedstocks. While developed for orbital manufacturing and future ISRU pathways, the same innovations will set a new performance and cost benchmark for terrestrial industries—including aerospace, automotive, med-tech, and advanced materials R&D—bringing a step-change in flexibility, efficiency, and part quality to Earth-based production.

Multi-material

One printer, endless possibilities

Seamlessly manufacturing gradient metal components, new alloys, and ceramics in a single device. It will empower engineers to design functionally graded, high-performance parts without the constraints of traditional single-material processes.

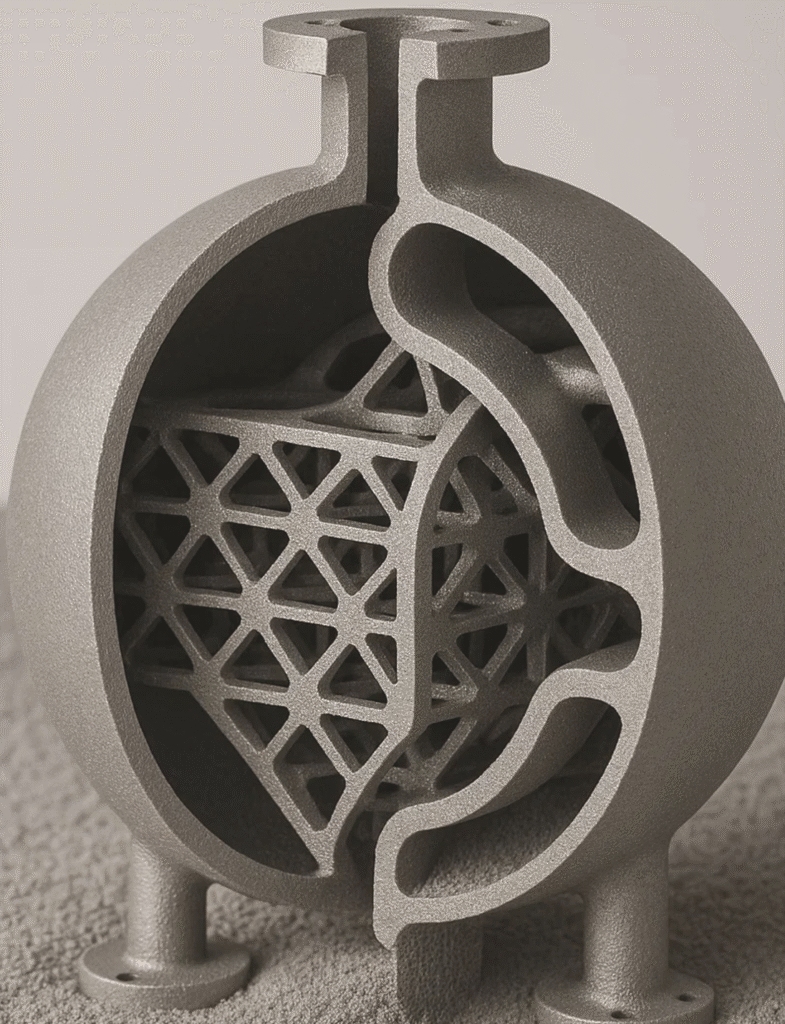

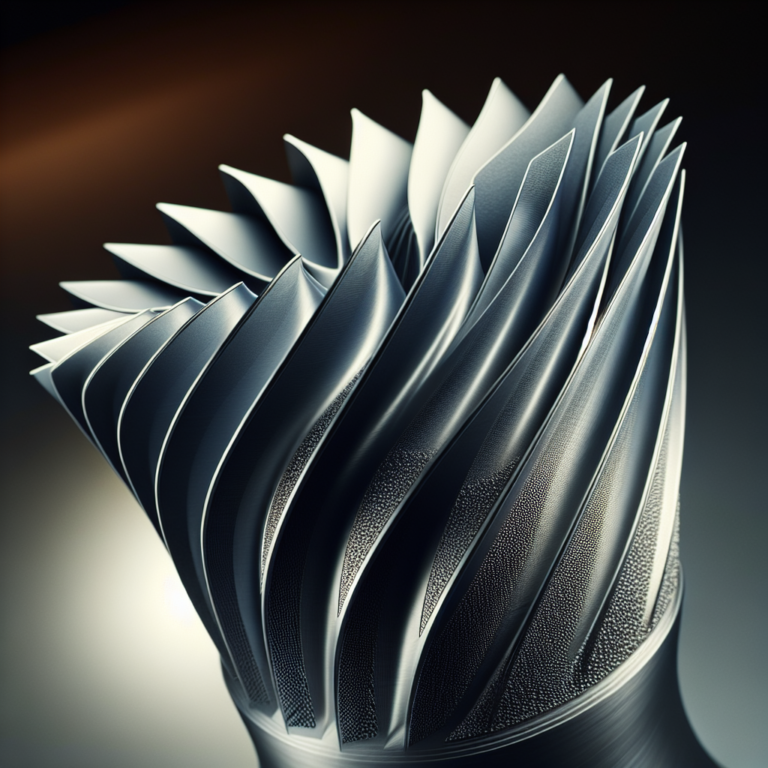

Supportless

Unleashing true design freedom

Our supportless 3D printing enables complex geometries, smoother surfaces with minimal post-processing, and reduced material waste for more efficient and precise manufacturing. It will give engineers the freedom to build parts previously impossible or prohibitively expensive to produce.

In-space use

Redefining manufacturing beyond Earth

Our in-space printing technology enables on-demand production of critical components in microgravity, ensuring spacecrafts’ missions resilience, reduced logistics, and greater autonomy for space operations.

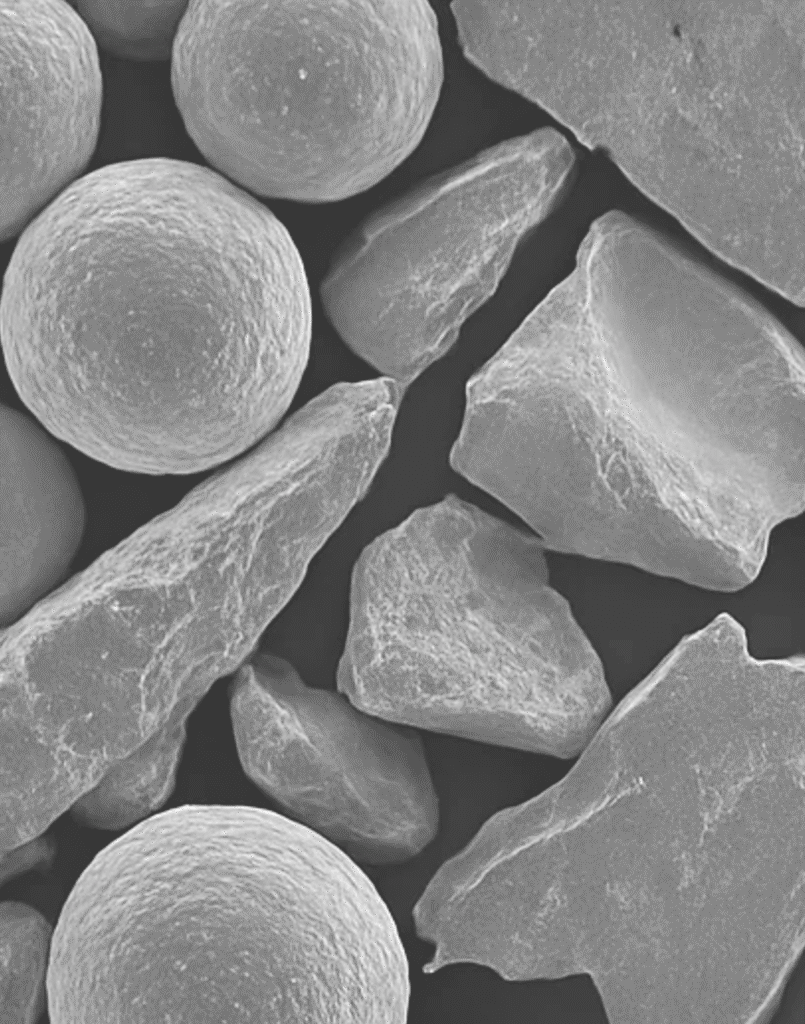

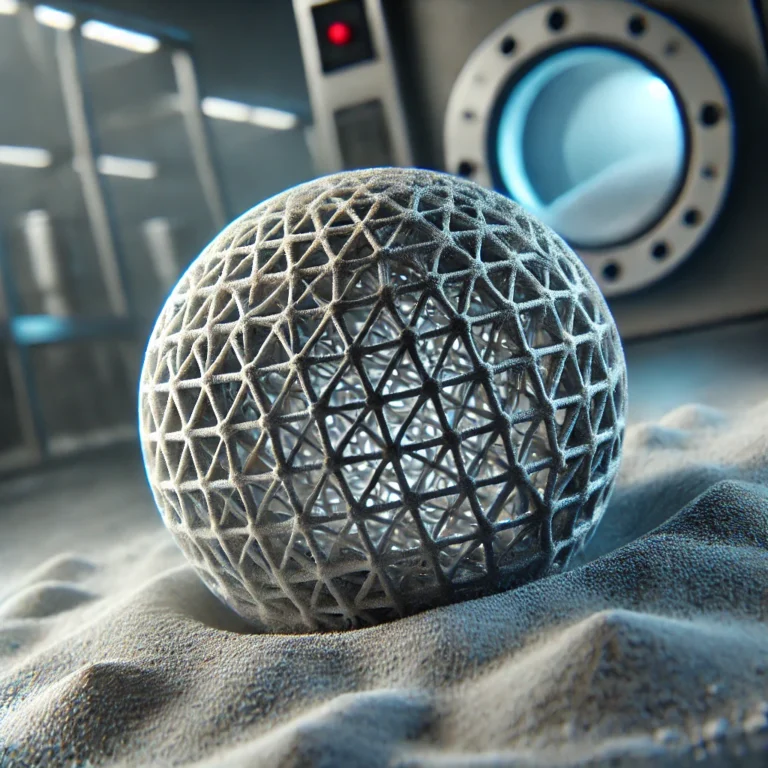

Cheaper feedstock

Low-cost powders for high-impact manufacturing

Spaceform’s technology will use non-spherical, recycled, and non-atomized powders, slashing material costs and enabling new industrial applications. Designed for Earth and in-space In-Situ Resource Utilization (ISRU), it will turn locally available raw materials into advanced metal, ceramic, and polymer parts.

APPLICATIONS

Spaceform’s cutting-edge technology aims to transform the aerospace, medical, energy, and tooling sectors with precise, multi-material manufacturing. Utilizing supportless printing, gradient materials, and low-cost non-spherical powders, it significantly cuts material expenses, boosts performance, and enables complex geometries previously unattainable. Designed for both terrestrial and microgravity environments, it will reshape production workflows and unlock new design possibilities across critical industries

Industrial & Advanced Manufacturing

On-demand Spacecraft maintanance

Space missions often store spare parts, though most go unused due to unpradictable nature of failures. Spaceform transforms this with in-space 3D printing, allowing on-demand repairs and upgrades. This cuts storage, resupply missions, and response times, boosting autonomy, and sustainability.

Research & Development (R&D)

We accelerate next-generation R&D with rapid, flexible experimentation in metals, ceramics, polymers, and advanced composites. Leveraging suspension-based 3D printing and low-cost non-spherical powders, we enable fast iteration of new alloys, graded structures, and novel material combinations — unlocking discoveries and process insights unattainable with conventional AM.

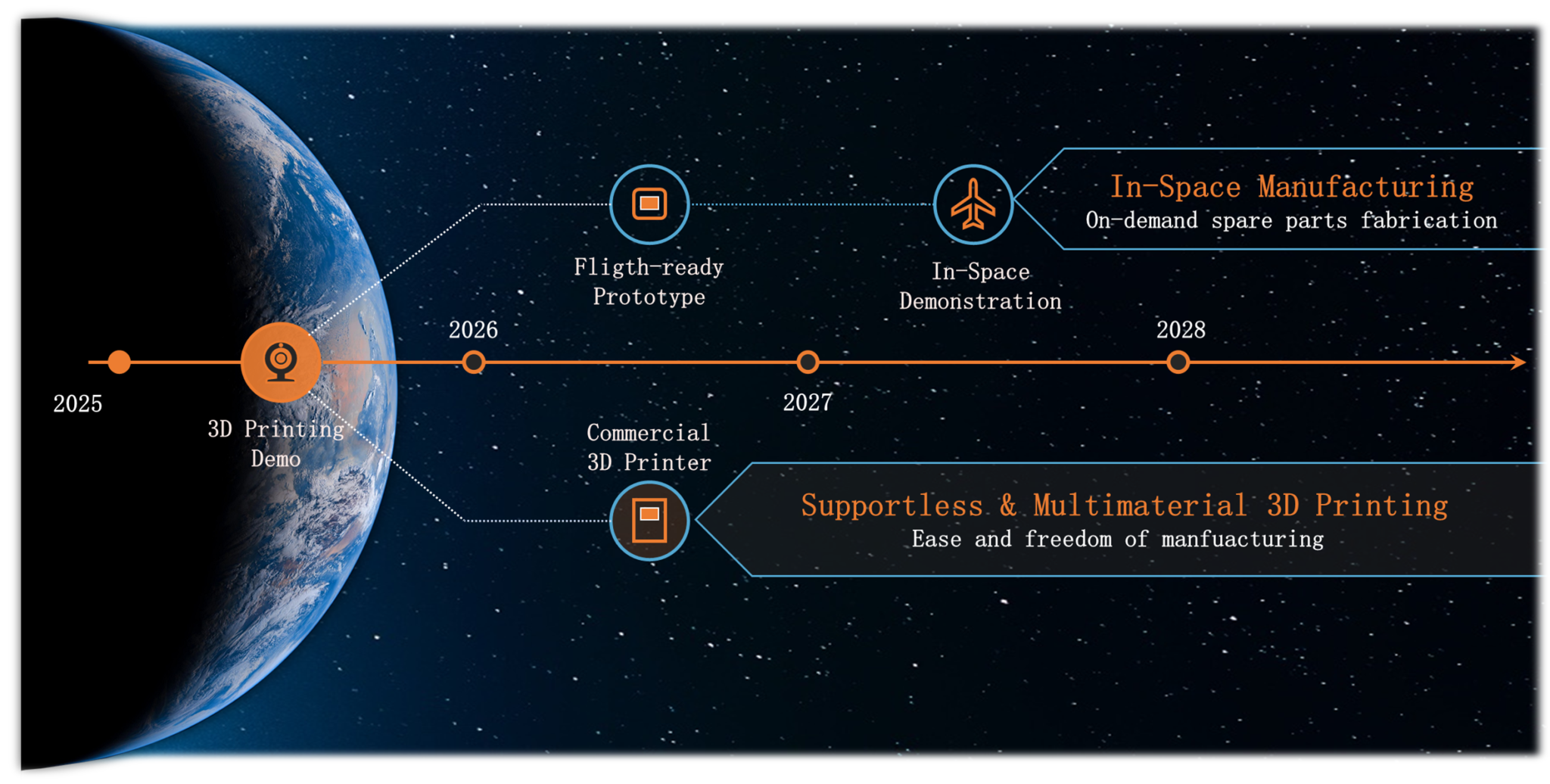

DEVELOPMENT ROUTES & PROGRESS

Team that drives the vision

Dr Krzysztof Fryzowicz, CEO

Passionate about solving and overcoming complex challenges, Krzysztof brings vision, creativity, and determination, driving Spaceform toward the future of advanced manufacturing.

Dr Hubert Pasiowiec, CTO

An expert in additive manufacturing, Hubert leads the technological development of Spaceform’s breakthrough 3D printing solutions, ensuring innovation meets real-world applications.

prof. Piotr Bała, CRDO

With a years of experience in materials science and engineering, Piotr oversees research, development and prototyping, pushing the boundaries of multi-material and supportless 3D printing technology.

Want to be next?

Our Partners

Contact Form

Join Us Today!

office@spaceform.eu

Headquarters

Czarnowiejska 36/C5-017

Kraków, Poland

Facility

Śniadeckich 20D/7

Rzeszów, Poland